Reducing energy consumption and providing clean water sources for industrial processes

In an effort to clean up industrial wastewater, experts have been searching for ways to save and recover energy and valuable materials from wastewater that is produced in manufacturing, the oil and gas industries, and in the power sector. The maturation of forward osmosis (FO) and membrane distillation (MD) technology has provided opportunities for expanding and realizing new water treatment and reuse opportunities.

We have developed an advanced hybrid system that integrates FO and MD to cost-effectively enable water reuse efficiency toward zero-liquid discharge. This approach can substantially improve energy efficiency of wastewater treatment relative to current technology. The combined technology also has the potential to utilize low-grade or waste heat to power the process.

Employing Hybrid Membrane Systems to Treat High-Salinity Water

Limited technology options exist for treating high-salinity water, and little progress has been made in this field for more than 30 years. Our team saw this challenge as an opportunity to develop a technology that can be an alternative to the current state-of-the-art methods for desalinating high-salinity water. We identified a significant gap between the salinity ranges that can be treated economically by reverse osmosis and thermal evaporators.

Using this determination, we chose membrane distillation, with its very high salt rejection to recover water from the draw solution of forward osmosis. This way, we can treat industrial water with salinity much higher than seawater, such as water found in oil and gas production sites and CO2-injection deep aquifers. Conventional reverse osmosis is technically not suitable as thermal evaporation is very expensive for this salinity range.

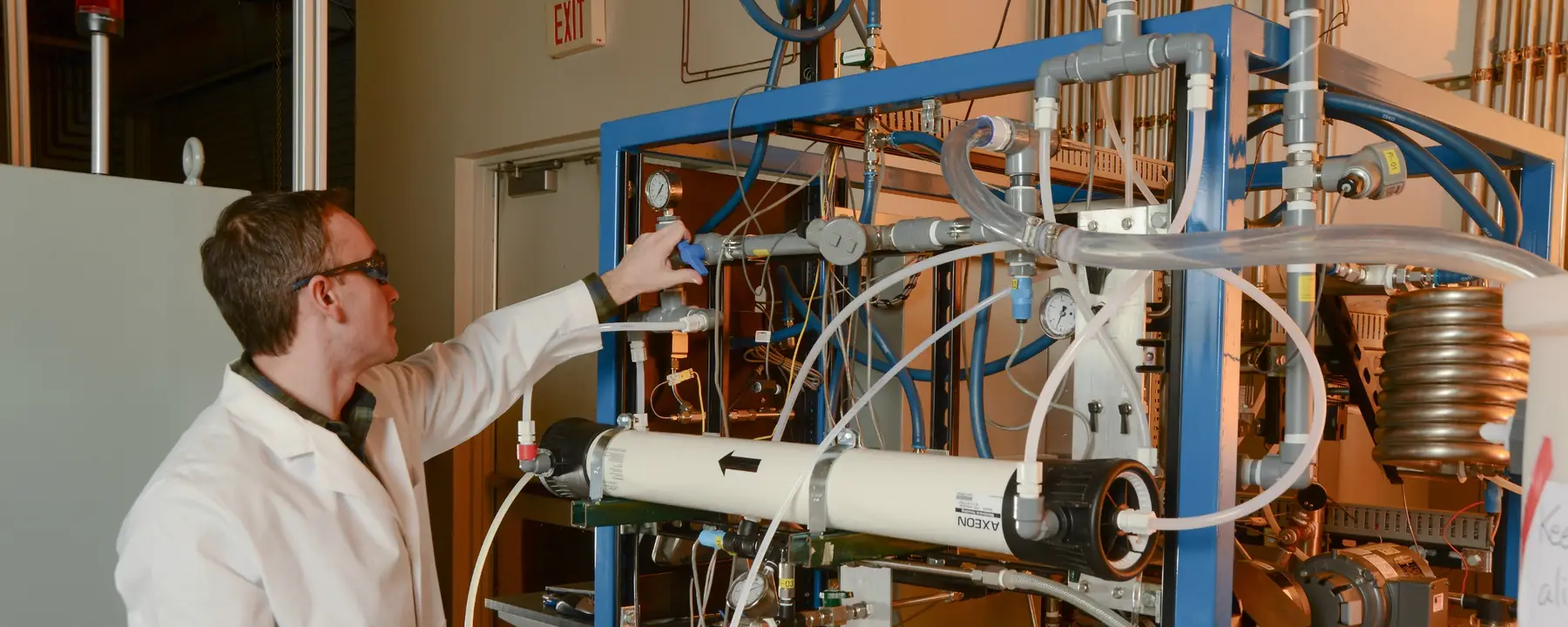

Our team has set up a water test facility to help streamline the transition to this approach from proof-of-concept and feasibility stage to actual testing and validation on actual industrial water streams. We have scaled the technology to a large bench-scale integrated FO/MD system, which will eventually be implemented in a water treatment plant at a partner site.

We also built a mobile water lab with an integrated test and analytical system that allows us to test the advanced hybrid technology at industrial host sites.

Mobile Water Treatment Lab Enables Recovery of Raw Wastewater

Our team operates a pilot-scale, integrated FO/MD prototype system with a nominal water production capacity of 500 gallons per day. The trailer-mounted mobile test system is designed to perform either at RTI or at field sites.

Most recently, the system was used for the treatment of brine concentrate derived from the reverse osmosis (RO) treatment of raw, oil field–produced water. Due to the concentrations of organics, oil, and grease in the RO brine, no further water recovery could be done on this wastewater by conventional treatment technologies. This opportunity allowed FO/MD to be considered as a potential solution to treat very high-salinity waste water.

Real produced-water RO brine having roughly 14,000 ppm totally dissolved solids (TDS) was shipped from an oil production site to our campus for pilot testing. The FO/MD prototype was used to first preconcentrate this brine to higher TDS levels in the range of 30,000–180,000 ppm. The prototype was then operated for several days to weeks with the resulting preconcentrated, higher-TDS brine as feed to determine system performance, as well as the maximum water recovery achievable and the maximum TDS level to which the FO/MD system could concentrate the industrial oil field–generated brine.

From the prototype operational data collected, the hybrid FO/MD process was found to be particularly suited to treat waters having high TDS content (i.e., 50,000–200,000 ppm) that state-of-the-art RO cannot handle and waters with high oil and grease concentrations that cannot be treated by thermal processes.

Leveraging New Materials and Water Sources to Reduce Waste and Water Treatment Costs

The most important metrics for any new water technology can be either to reduce the levelized costs of water or enable previously unusable water to become a viable, new water source. For example, besides improving energy efficiency, we aim to lower the cost of construction by using low cost polymeric materials instead of exotic alloys. In addition, we are seeking to recover water from deep aquifer brine, which previously was regarded as a waste rather than a resource.

- DOE-EERE (Advanced Manufacturing Office)

- Duke University

- Veolia Water Solutions & Technologies North America

- Inc.